More

Capsule on fire – Apollo 1 Bodies

The success of Apollo 11 proves that the human species is capable of great things. In turn, the fate of the Apollo 1 bodies is a brutal reminder that achieving the most ambitious goals usually requires paying the highest price.

Failures await

Soon, exactly half a century will have passed since the most famous walk in the history of mankind. In July 1969, the late Neil Armstrong became the first man in history to set foot on an alien globe. To say that this event was a great achievement is to say nothing. Think about it. It took us just 66 years to go from Orville and Wilbur Wright’s primitive biplane to the monumental Saturn V rocket. This is an unprecedented technical, scientific and mental leap.

It’s so easy to forget that the legendary Apollo program had the worst possible start. Before anyone left the ground, the entire Apollo 1 bodies burnt during a routine test.

Preparations for the mission

Contrary to the nomenclature, Apollo 1 was not the very beginning of the entire program. For six years, NASA has been organizing tests of subsequent versions of the designed launch vehicle – designated as Saturn-Apollo. In February 1967, it was planned to enter the decisive stage of the project. The new equipment was to be used to put three people into orbit for the first time.

Image credit to: universetoday/pinterest

The Astronaut Trio: Assembling the Team

The commander, Guss Grissom, was one of the first seven American astronauts in the Mercury program. Interestingly, he has already found himself in a mortal danger situation once. At the end of the Mercury 4 mission, after a successful splashdown, the capsule’s hatch unexpectedly blew up (remember this fact and you will appreciate the grim irony). Grissom almost drowned. The second member of the team was Edward White. He gained fame during the Gemini 4 mission, completing the second (after Alexei Leonov) spacewalk. The youngest, Roger Chaffee, was originally one of the reserves and was just waiting for his debut. He was hired to replace the experienced John Glenn, who dislocated his shoulder… by slipping in the bathroom. We can only imagine Chaffee’s joy at the news of his sudden promotion in the hierarchy and increased chances of writing his name on the pages of history.

Simulation Challenges: The “Plug Test” Incident

The plan was simple. On February 21, the IB variant Saturn rocket was to carry the module and astronauts to low orbit, where they would remain for two weeks before returning safely home. As is usually the case, the start was preceded by arduous training of people and equipment tests. One such routine simulation – the so-called “plug test” – was conducted on the afternoon of January 27, 1967, at launch pad 34 of the Cape Canaveral Space Center.

There was an atmosphere of Friday relaxation. The several-hour test was coming to an end, and everyone was about to go home for the weekend. One issue that still left much to be desired was radio communication. The communication was accompanied by annoying cuts and noises, even though the technicians were only a dozen or so meters away from the capsule. As Guss Grissom aptly observed: “We want to communicate with the Moon, and we can’t talk sitting three buildings away from each other.” Around 6:30 p.m., the controllers heard indistinct words in their headphones:

Fire! We have fire here!

In any other situation, this would have triggered an immediate reaction, but this time there was a few seconds of hesitation. The schedule included space for exercises in an emergency situation, so the employees’ first instinct was to treat the announcement as part of the training. Only further, difficult to understand shouts convinced everyone that something had gone wrong. Inspector Henry Rogers, Chief Engineer Jim Gleaves, and several others grabbed fire extinguishers and took the elevator to the white room , a small room immediately adjacent to the module. When they got there, in a panic they couldn’t find the Allen key needed to open the hatch from the outside. Meanwhile, an orange flash appeared in the small window. In fact, there was no chance of a successful rescue. Grissom, White and Chaffee died within 14-20 seconds of ignition.

An expensive lesson

How did such a tragic accident occur during a common test? First of all, we must pay attention to what the astronauts were supposed to breathe. It was not ordinary air, but pure oxygen – and this, as you probably know from your chemistry lessons, goes very well with fire.

Of course, it was about saving money. NASA reasoned as follows: instead of carrying a kilogram of air containing 21% of life-giving oxygen into space, it would be better to pack 1/5 kilogram of oxygen only. It also made design sense because it reduced the pressure difference between the interior of the ship and the vacuum of space. (It is worth emphasizing here, however, that during the test itself the pressure inside the cabin was even higher than atmospheric!) Currently, even on board the ISS, mixtures are used that are closer in composition and pressure to the Earth’s atmosphere.

The legacy of Apollo 1

The 1967 disaster caused a great stir. Not even because of the fact that three people died, but because of the circumstances. This is well reflected in the words of Apollo 7 mission participant,

Walt Cunningham:

We expected from the beginning that we would lose at least one crew before we could land on the Moon. (…) However, we did not expect that we would lose people on Earth.

John Tribe

NASA employee John Tribe also shared an interesting conclusion:

My subjective feeling is that without the loss of 1967, we might have literally never gotten to the Moon. What we learned from this accident made the program safer.

How much are we willing to sacrifice?

The question remains: how would NASA, politicians and ourselves react if such a tragedy happened today? These are not idle considerations, but a problem that we will have to face again, even in the perspective of a manned mission to Mars. What will happen if the first mission to the Red Planet ends in a complete failure and results in the death of the crew? Let’s make no mistake, such a scenario remains very likely. And when a tragedy does occur, we will immediately hear a chorus of a thousand heads calling for the program to be immediately stopped and not to risk the lives of any more men and women.

FAQs

Did they find the bodies of Apollo 1?

Grissom, Chaffee, and White were found dead inside, ages 40, 31, and 36 respectively. Autopsies determined that they died from toxic smoke inhalation and burns. This information was provided by the National Air and Space Museum.

What happened to Apollo 1 astronauts?

On Jan. 27, 1967, Gus Grissom, Ed White, and Roger Chaffee tragically lost their lives in a flash fire inside the Apollo 1 crew capsule during a launch test rehearsal.

What were the last words of Apollo 1?

Chaffee announced a fire. Shouting followed. Crew communication stopped 17 seconds after the fire began. All telemetry was lost. The Apollo hatch opened inward and was secured by latches operated with ratchets.

Where is the crew of Apollo 1 buried?

Arlington National Cemetery has memorials for the crews of the 1986 Space Shuttle Challenger and 2003 Space Shuttle Columbia tragedies. However, there is no memorial for the Apollo 1 crew, even though Grissom and Chaffee are buried there. White, on the other hand, is buried at West Point.

Read Also:

More

How to Achieve Consistent Results with Your Paint Spray Booth

Achieving consistent results in a paint spray booth involves more than just having the right equipment. It’s about fine-tuning various aspects of your booth to ensure the best possible outcomes. Here are some uncommon yet effective strategies to enhance the performance of your paint spray booth.

Implement Ionic Air Purification

Maintaining a clean environment inside your paint spray booth is crucial for achieving high-quality finishes. Ionic air purification systems can significantly reduce airborne contaminants. These systems work by emitting negative ions that attract and neutralize particles such as dust, pollen, and even smoke. By incorporating ionic air purifiers, you can ensure that the air inside your booth remains clean and free from particles that can compromise your paint job. This is especially beneficial for those using a high-tech spray paint booth or a commercial spray paint booth where precision is key.

Use Pulsed Air Filtration Systems

Traditional filtration systems can only do so much to keep the air inside your booth clean. Pulsed air filtration systems, on the other hand, provide an advanced level of air purification. These systems use short bursts of compressed air to remove accumulated dust and particles from the filters, ensuring that they remain unclogged and effective. This method not only prolongs the life of your filters but also maintains optimal airflow within the booth, which is essential for achieving a consistent finish. Whether you have a large paint spray booth or a small spray paint booth, incorporating pulsed air filtration can make a noticeable difference.

Calibrate Booth Lighting for Color Accuracy

One of the most overlooked aspects of achieving consistent results in a paint spray booth is lighting. Calibrating your booth lighting to ensure color accuracy can prevent costly mistakes. High-CRI LED lights are ideal for this purpose as they provide a natural and accurate color representation. By adjusting the lighting to mimic daylight conditions, you can ensure that the colors you see in the booth are true to their actual appearance. This is particularly important for professionals using a professional spray paint booth or those offering spray paint booth rental services, where client satisfaction is paramount.

Install Smart Humidity Control Modules

Humidity levels inside your paint spray booth can have a significant impact on the final result of your paint job. Installing smart humidity control modules allows you to monitor and adjust the humidity levels in real-time. These modules can automatically regulate the humidity to maintain optimal conditions for painting, preventing issues such as blistering or uneven drying. This technology is a must-have for any affordable paint spray booth or custom spray paint booth aiming to deliver consistent, high-quality results.

Adopt Electrostatic Grounding Techniques

Electrostatic grounding is a technique that can greatly enhance the efficiency and consistency of your paint spray applications. By grounding the object being painted, you can reduce overspray and ensure that the paint particles are attracted to the surface evenly. This method not only improves the quality of the finish but also reduces paint waste. Implementing electrostatic grounding is particularly beneficial for those using a mobile spray paint booth or a ventilated paint spray booth, where portability and efficiency are critical.

Utilize Airflow Visualization Tools

Understanding and optimizing the airflow within your paint spray booth is essential for achieving consistent results. Airflow visualization tools, such as smoke sticks or digital airflow meters, can help you identify and correct airflow issues. By visualizing the airflow patterns, you can make adjustments to ensure that the air moves evenly throughout the booth, preventing areas of turbulence or stagnant air. This is crucial for maintaining a dust-free environment and achieving a smooth, even finish. Whether you are using a home spray paint booth or an industrial spray paint booth, these tools can provide valuable insights.

Maintain Your Spray Booth Regularly

Regular maintenance is key to ensuring that your paint spray booth continues to perform at its best. This includes routine cleaning, filter replacements, and inspections of all mechanical and electrical components. A well-maintained booth will not only produce consistent results but also have a longer lifespan. For those offering spray paint booth installation or spray paint booth maintenance services, emphasizing the importance of regular upkeep can help clients achieve the best possible outcomes.

Achieving consistent results with your paint spray booth requires a combination of advanced technologies and diligent maintenance. By implementing ionic air purification, pulsed air filtration systems, calibrated booth lighting, smart humidity control modules, electrostatic grounding techniques, and airflow visualization tools, you can ensure that your booth operates at peak performance. These strategies, coupled with regular maintenance, will help you deliver high-quality finishes every time, whether you’re working with a small spray paint booth or a large paint spray booth.

More

Enhancing Efficiency: Signature Stamps for Checks

Optimize your check-signing process with signature stamps designed specifically for checks. Experience efficiency and security in one simple tool.

The domain of signature stamps goes beyond mere simplicity, holding deep importance in both personal and professional fields. These instruments are crafted to replicate signatures swiftly and reliably, fostering convenience and dependability. In this discourse, we delve into the multifaceted domain of signature stamps, encompassing their categorizations, applications, pre-purchase considerations, operational efficacy, potential limitations, and associated risks.

Varieties of Signature Stamps:

Pre-inked Signature Stamps:

These stamps feature an integrated ink reservoir within the stamp pad, ensuring consistent and lucid impressions.

Self-inking Signature Stamps:

Equipped with an internal ink mechanism that replenishes ink after each use, these stamps cater excellently to frequent applications.

Rubber Stamp Signature Stamps:

Traditional in nature, these stamps necessitate a separate ink pad while offering adaptability in terms of customization.

Utilizations and Implementations:

The application spectrum of signature stamps spans diverse domains:

Commercial and Corporate Utility:

Facilitating paperwork streamlining, document endorsements, and personalized correspondence augmentation.

Personal Integration:

Simplifying tasks such as check endorsements, document signing, and letter authorization.

Legal and Administrative Utilization:

Ensuring uniformity and expediency in administrative undertakings and legal documentation authentication.

Pre-Purchase Considerations:

Before committing to a signature stamp acquisition, it is imperative to contemplate:

Imprint Quality Assurance:

Ensuring the stamp yields legible and coherent impressions consistently.

Endurance and Longevity:

Opting for stamps fashioned from resilient materials capable of withstanding recurrent usage.

Customization Parameters:

Selecting stamps that accommodate customization of signature designs and supplementary text.

Compliance with Legal Precepts:

Familiarizing oneself with legal stipulations concerning signature stamp usage within one’s jurisdiction.

Operational Guidelines for Signature Stamps:

To maximize the efficacy of signature stamps, adhere to the following guidelines:

- Adequate Handling and Safekeeping:

- Store stamps in secure confines and handle them judiciously to avert potential damage.

- Imprint Clarity Assurance:

- Apply uniform pressure during stamp deployment to engender sharp and distinct impressions.

- Integrity Maintenance Strategies: Safeguard stamps against unauthorized access and misuse to forestall fraudulent activities.

Potential Limitations and Risks:

While signature stamps epitomize convenience, they harbor inherent risks:

Forgery Vulnerability:

Unauthorized access to signature stamps poses the risk of perpetrating fraudulent activities.

Legal Ramifications:

Acquaintance with the legal repercussions of signature stamp utilization, particularly in contractual and official document contexts, is imperative.

Risk Mitigation Measures:

Implementation of security protocols, including access restriction and surveillance, is paramount in curbing potential misuse.

Conclusion:

In summation, signature stamps emerge as indispensable assets that streamline operational workflows, augment efficiency, and inject a personalized essence into documentation. By assimilating insights into their variants, applications, considerations, and attendant risks, individuals and enterprises can harness the transformative potential of signature stamps adeptly while avoiding associated pitfalls. Whether endorsing checks, validating documents, or optimizing administrative processes, signature stamps represent an ideal solution catering comprehensively to diverse signing requisites.

FAQs:

Are signature stamps legal?

Certainly, signature stamps commonly serve as a legally recognized form of authorization.

How do I get a stamp of my signature?

You can get a stamp of your signature by creating a digital image of your signature and ordering a custom stamp online or at a stationery store.

Can you use signature stamps on checks?

Certainly, signature stamps can typically be used to sign checks, but it’s essential to take precautions. Individuals should update bank records to validate the use of stamps and closely control access to prevent any misuse.

Read Also:

Pros and Cons of BYOD: Opportunities and Risks For Companies

More

How To Choose a Good Watermelon? 4 Simple Tips

Watermelon is a must-eat fruit in summer. It is cool, juicy and sweet. Whether eaten directly or made into juice, it can bring a touch of coolness to the summer. However, there are many questions on how to choose a good watermelon based on its appearance. This is a major problem for consumers. Regarding this, the Agri-Food and Food Administration has personally revealed 5 tips so that everyone will never make a mistake when buying watermelon!

How to choose a watermelon?

Although it is difficult to define the ripeness of a fruit simply based on its exterior, there are still some ingenious ways to choose your Watermelon. We will reveal the secrets to you today!

Size and Shape

Good watermelons are generally medium sized, neither too small nor too large. The juiciest watermelons are generally heavier because they are full of water. The shape of a good watermelon is necessarily symmetrical or homogeneous: this indicates that it received a regular amount of water and sunlight during its growth. The presence of dents or cuts signals the opposite.

The Skin

This famous skin which prevents you from seeing the flesh inside to judge the condition of the fruit is, in truth, an indicator. And if we have to remember just one thing, it’s that a beautiful, unblemished watermelon will never be the best. The yellow spot present on watermelons is one of the most important criteria. This stain is completely normal: it forms on contact with the ground. The more yellow or orange this spot is, the darker it is, the tastier the watermelon will be. If the spot is white, it indicates that the fruit was harvested too early.

The gray traces, like spider webs, also guarantee a good sweet taste. In fact, these traces are a sign that the bees have come in large numbers to forage on the watermelon . And if these came, it was because the fruit was very sweet. Of course, this can be annoying for recipes where you have to use the skin of the watermelon (because yes, everything is eaten in the watermelon). You will then have to make a choice based on your needs. Finally, the skin of a watermelon should have a matte appearance and be a deep green color. The shine means it is not yet mature.

Touch the stem of the watermelon to identify a ripe fruit

The stem of a watermelon is also a good way to know its ripeness. A very green tail indicates that the fruit was harvested too early. Conversely, a very dry stem is a sign that the watermelon has reached a good level of maturation and is ready to be enjoyed.

Identify a good watermelon by tapping it

Watermelon fans have a special trick for recognizing a good fruit : it involves tapping the skin with your fingers. If the watermelon makes a full, tenor sound, it is ready to be eaten. Conversely, a deep or hollow sound means the fruit is unripe. The difference may seem small, but fruit lovers always get there in the end.

How to store it?

The best is to keep it in the refrigerator!

Unopened, you can easily store your watermelon for a week, preferably in a cool, well-ventilated place. If, on the contrary, it is already started, protect its flesh with cling film to prevent it from getting damaged and drying out.

And there you have it, thanks to these tips you will become a pro when choosing your Watermelons.

FAQs

How to choose a delicious watermelon?

Because as the watermelon matures, a large part of the water content will be expelled and more sugar will accumulate, so the weight of the mature watermelon is always lighter. So choose lighter watermelons of the same size. To sum up, when choosing a watermelon, you should choose one with a small navel, a curved base, clear lines, a crisp and vibrating sound when struck, and a light weight. Have you learned this?

What to do with unsweetened watermelon?

Methods/steps: Cut the watermelon into even and unequal portions, and sprinkle some salt and sugar on top . This will change the original tasteless taste of the watermelon from the outside. It is also a way to eat it, but before doing so, it is best to put the watermelon in the refrigerator. Freeze it and make it again, it will taste better.

Read Also:

-

Top2 years ago

Top2 years ago2022 US House committee releases Trump’s tax returns, capping a years-long battle

-

Auto1 year ago

Auto1 year agoTop Porsche Taycan Incentives: Save Big

-

Business1 year ago

Business1 year agoBeware Of Fake Emails And Fake Apple Pay Images

-

Business1 year ago

Business1 year agoDoes 7-Eleven Take Apple Pay

-

Top2 years ago

Top2 years agoInterview With Niantic CEO John Niantsullivan

-

News1 year ago

News1 year agoUSPS EMPLOYEE ASSISTANCE PROGRAM SERVICES AND BENEFITS

-

Top1 year ago

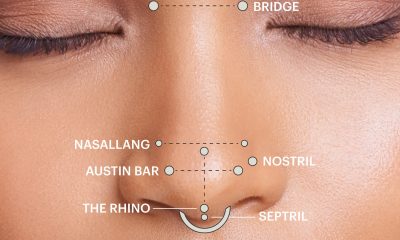

Top1 year agoUnderstanding the Healing Process of Nose Piercings – A Comprehensive Guide

-

Cryptocurrency1 year ago

Cryptocurrency1 year agoBridging the Gap: Binbex Futures